Speed

With a machinability rating of 100, brass offers greater production efficiency than 12L14 steel or 304L stainless steel (Thiele et al., 1990). Machinability tests show that brass achieves much higher metal removal rates than steel and stainless steel with dramatically longer tool life. In high-speed turning, brass maintains good surface finish and excellent chip control, and high-speed drilling with brass can produce more holes in less time with lower risk of tool failures under aggressive conditions.

Drilling speed limit testing for 304L, 12L14 and a lead-free brass

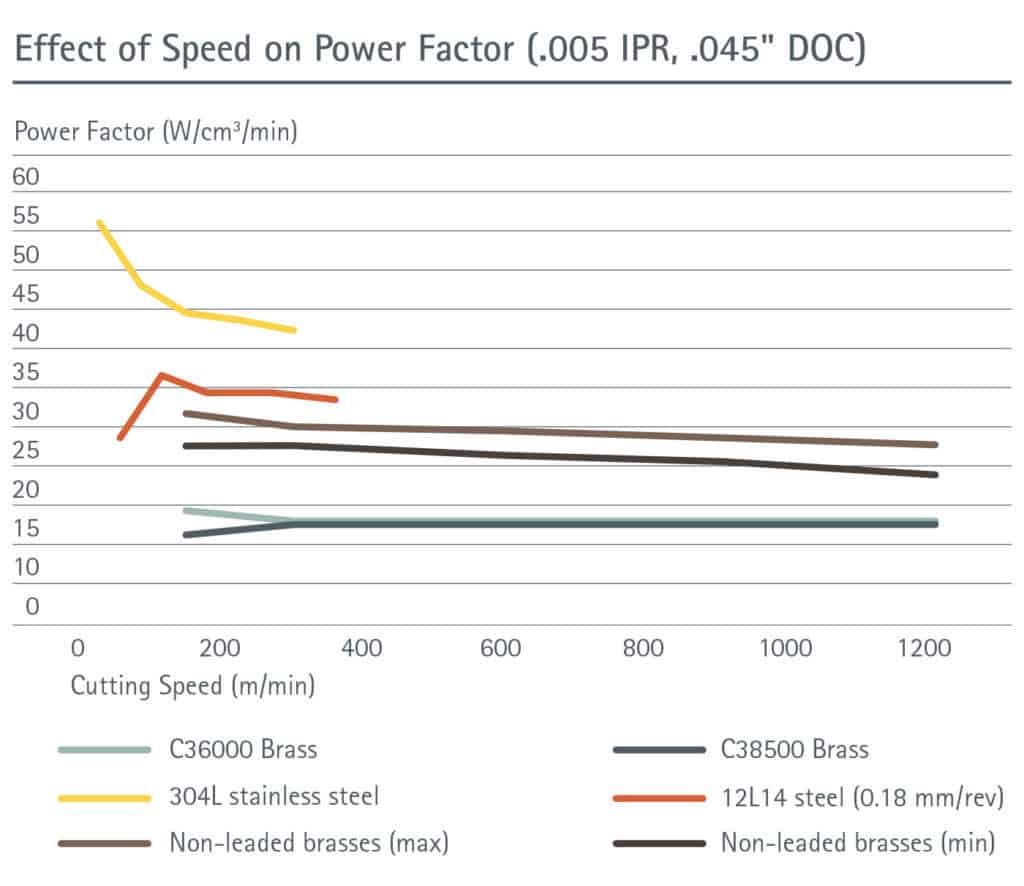

Optimized turning tests also revealed 12L14 steel and 304L stainless steel to be nearly 2x and 2.7x less energy efficient than machining brass, respectively, because they require much more power to remove the same amount of material. The lower cutting forces afforded by brass mean less wear on equipment, and lower energy and maintenance costs. More importantly, brass allows for higher material removal rates, which means lower machining costs compared to steel or stainless steel.

Effect of increasing speed on efficiency for all materials at a fixed mid-range feed

Lower power factor values = higher efficiency

Because of faster cutting speeds, lower energy requirements and longer tool life, optimized machining with brass can reduce per-part costs well below those for steel and stainless steel. In turning tests, 12L14 steel ran at only 30% of the top speed for brass, and 304L stainless steel managed only 20%. Tool life was at least 8x longer for brass than for steel and stainless steel at more than 3x the speed.

Turning speed/cost comparison*

| 304L stainless steel | 12L14 steel | Brass | |

| Maximum cutting speed with acceptable tool life (surface feet per minute; carbide inserts) | 800 | 1,200 | 4,000 |

| Optimized high-speed metal removal rate (in3 per minute) | 3.02 | 4.54 | 21.6 |

| Machining cost (per 1,000 in3 of material removed at $100/hr.) | $550 | $370 | $80 |

*Adinamis et al., 2019

In drilling tests, 12L14 steel achieved only 40% of the top operating speed for brass, and 304L stainless steel reached only 12%. Drill life for brasses was nearly 4x longer than for 12L14 and 304L, creating 4x the number of holes.

Drilling speed/cost comparison*

| 304L stainless steel | 12L14 steel | Brass | |

| Maximum cutting speed with acceptable tool life (surface feet per minute; carbide drills) | 250 | 800 | 2,000 |

| Optimized high-speed metal removal rate (in3 per minute) | 9.6 | 30.6 | 76.4 |

| Machining cost (per 1,000 holes drilled at $100/hr.) | $253 | $78 | $32 |

*Adinamis et al., 2019

High-Speed Machining Productivity

With the right equipment and tooling, shops that move beyond conventional, overly conservative cutting parameters can increase their productivity and profitability dramatically with brass. For example, a continuous 8-hour part run on a Swiss CNC lathe produced 63% more brass hose couplings with no quantifiable tool wear when optimized for high speed machining versus at conventional handbook speeds, reducing machine-time costs by 38.5% per part while maintaining tight tolerances.

Recyclability and Scrap Value

Beyond the improvements in profitability that come with optimized high-speed productivity, brass scrap also offers substantial benefits from a net-costing perspective. Steel and stainless-steel machining scrap retains only a fraction of its raw material value, so although ferrous scrap makes up more than 60% of U.S. scrap volume, it represents less than 50% of the total value traded. Conversely, brass rod, which is made almost entirely from recycled scrap and is 100% recyclable, often holds 75%-90% of its original value, allowing shops to offset raw material costs through closed-loop scrap buy-back programs. Read more about brass recycling in our latest white paper.

Brass yields shorter cycle times, greater throughput and higher scrap value than 12L14 steel or 304L stainless steel for better manufacturing economics. Shops recoup investments in high-speed machine tools faster with more-profitable parts, elevating the importance of brass in a productive workflow.

Recent Comments