Do the Math:

It Makes Cents To Spec Brass

The equation is simple. Reduced machining costs plus high scrap value equal lower cost per part. Overall, brass is the most cost-effective and sustainable solution available for today’s design challenges of longer lead times, tighter margins, and the demand for more sustainable materials.

While initial raw material costs might be higher in some cases than other machinable metals, the total lifecycle cost of brass is often less thanks to faster production times, lower tool wear, and high scrap value which all contribute to increased profit per part.

How Profitable Can Brass Be? Find Out

Considering its complete lifecycle, brass is one of the most cost-effective machining materials available. Use our Machine Tool Payback Calculator to input company-specific data such as raw material costs, cycle times, part weight and recycling value to discover just how beneficial designing with brass can be.

Brass Material Lifecycle

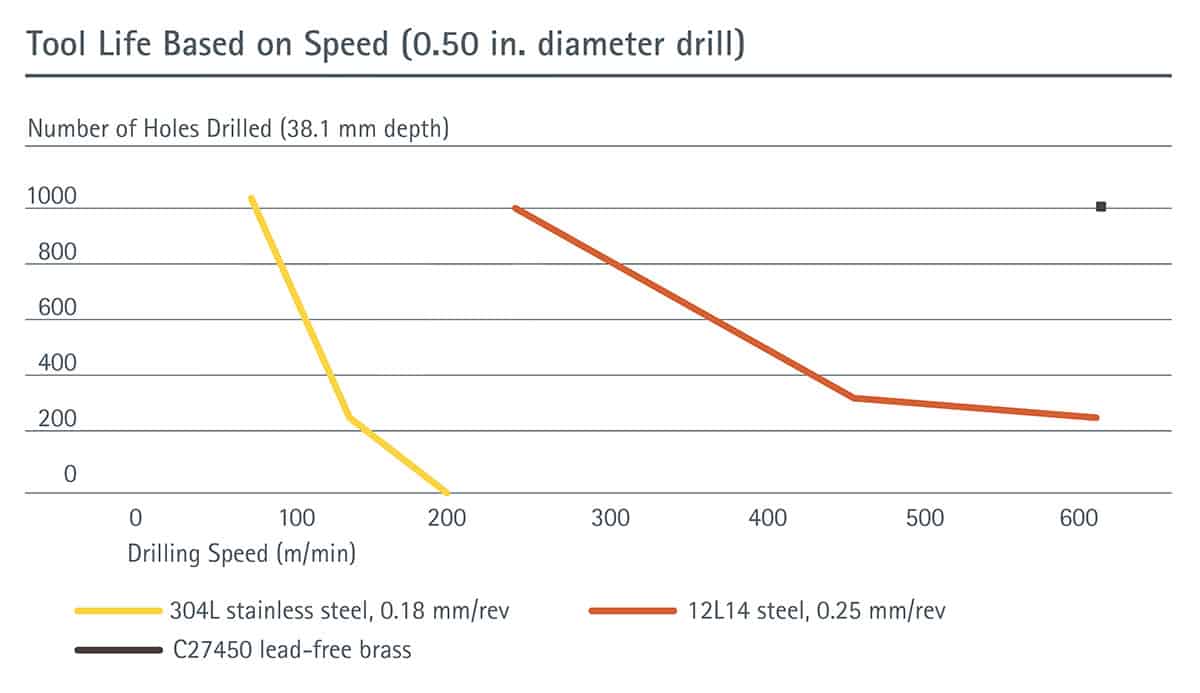

Faster Speeds and Feeds for Lower Cost Per Part

The math is simple: Less machine time equals lower cost per part – which means greater profitability for your business. Brass’ 100% machinability, faster cuts and shorter cycle times allow the job shop you choose to manufacture faster and more sustainably.

Improve Profitability Without Losing Performance

For many applications, brass can match or exceed critical performance requirements compared to steel, stainless steel, and aluminum. Extensive testing has also shown that machine cost per cubic inch of material removed can be 79% less than steel and 86% less than stainless steel for single point turning operations. In a drilling comparison, brass cost 59% less than steel and 87% less than stainless steel per 1,000 holes drilled.

Brass is also sustainable. Brass scraps are 100% recyclable and can be sold back to producing rod mills or scrap dealers for 90% or more of the original raw material cost. Brass rods produced in North America contain over 95% recycled content which helps manufacturers meet sustainability goals and reduce embodied carbon in products.

Considering Brass For Your Next Project?

Brass is readily available and perfectly suited for advanced machining of precision parts, offering significant productivity gains with long tool life. With its superior machinability and sustainability advantages, brass is uniquely designed to meet today’s demand for expanded production and reduced costs.

%