Brass turns fast.

Can your machines keep up?

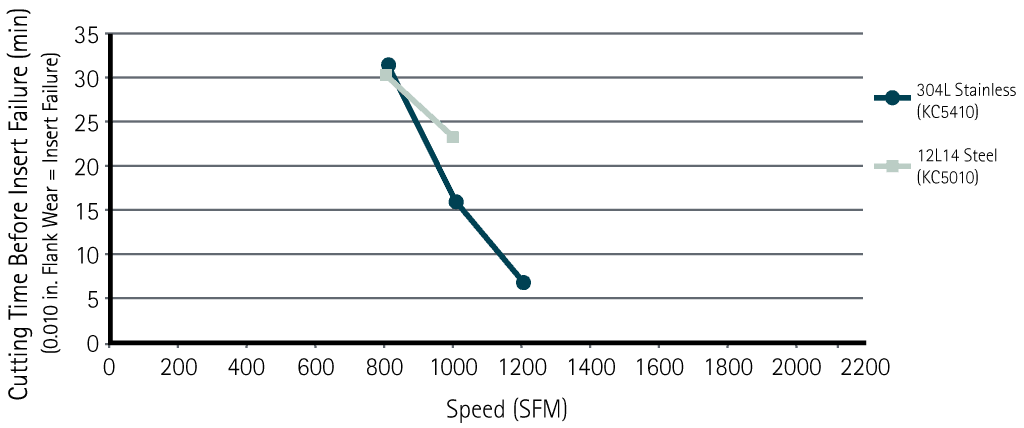

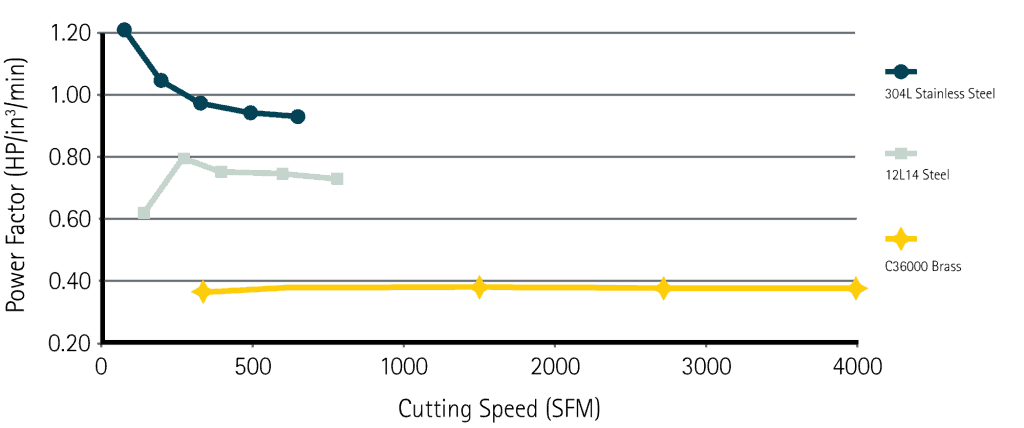

Maximum achievable metal removal rate defines high-speed turning productivity limits, based on achieving acceptable surface finish, reasonable tool life and manageable chip formation. A production test of turning speed limits achieved eye-opening results that favored brass. After 4 hours of continuous turning with carbide tools at speeds higher than 3,000 Surface Feet per Minute (SFM), brass alloys produced minimal tool wear. The test also achieved speeds up to 4,000 SFM (greater than 16,500 RPM) on brass for diameters above 0.90” with no excessive spindle vibration or chatter. By comparison, steel alloys reached their limits at significantly lower speeds than brass and required more horsepower to remove material. Notably, tool life was at least eight times longer for brass at more than triple the speed.

Brass turns fast.

Watch as brass turns at speeds exceeding 4,000 SFM without compromising chip control or surface finish. By comparison, steel alloys reached their limits at significantly lower speeds and required more power to remove material. Notably, tool life was at least eight times longer for brass at more than triple the speed.

Contact Us

Copper Development Association Inc.

1660 International Drive, Suite 600

McLean, Virginia 22102 USA